Digital imaging giant Teledyne DALSA is one of the most senior residents at High Tech Campus Eindhoven. Using state-of-the-art X-ray detectors for medical, dental and industrial applications their ambition is to be both world and innovation leader in their field. Their CMOS detectors provide superior image quality in real time and at a low dose.

Teledyne DALSA has set up shop at High Tech Campus Eindhoven from the day the Campus opened its doors to the outside world in 2003, taking over some of the activities of the old Philips NatLab. With about 140 employees at the Eindhoven location they’re quietly but relentlessly pursuing the path of technological leadership and have grown into a top player in the digital dynamic X-ray imaging market.

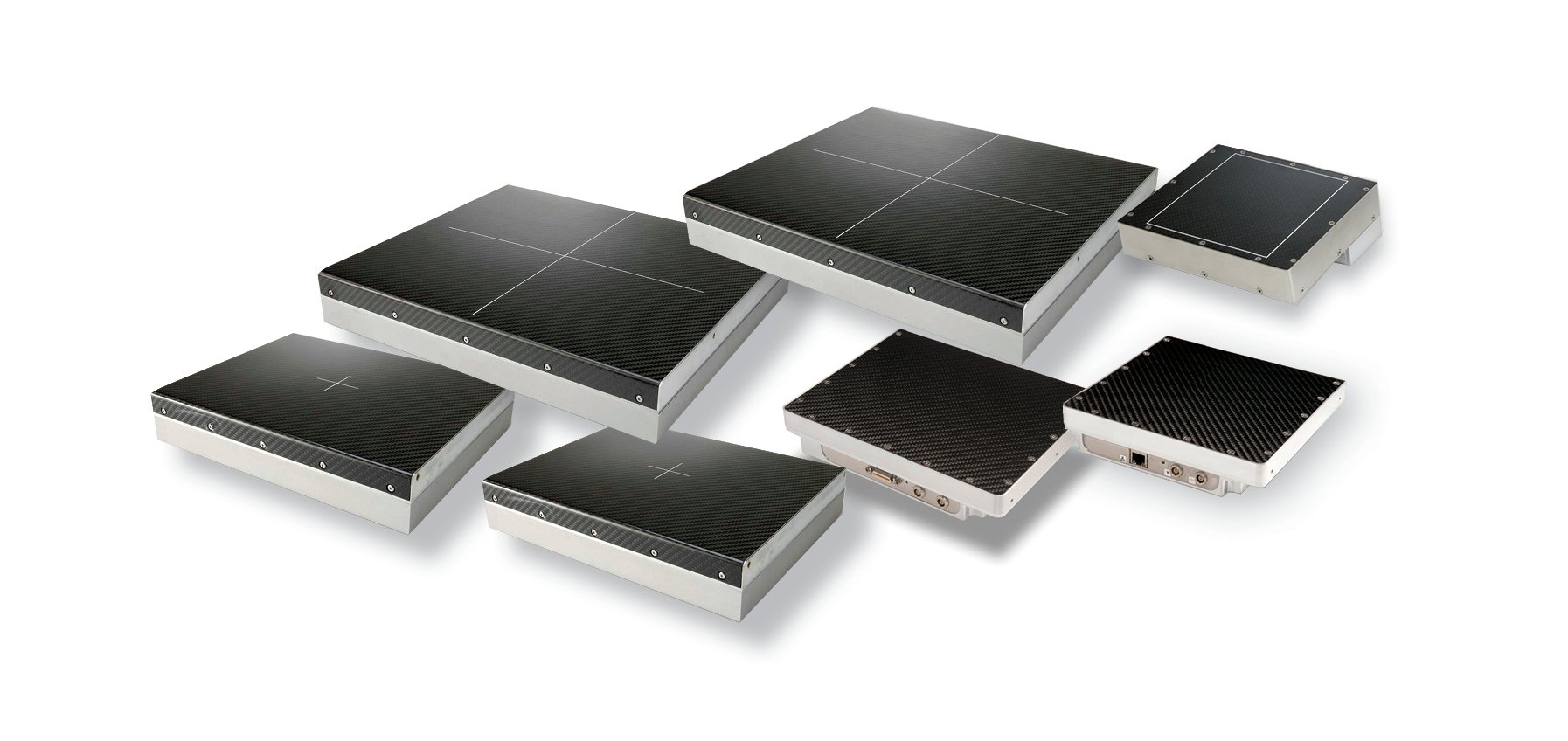

The company develops and produces sensors and detectors for digital imaging that are used in a wide variety of applications, ranging from digital cameras for machine vision to detectors for X-ray systems, to the onboard cameras on NASA’s space rovers used on the Moon and Mars.

X-ray videos

With offices around the world, the main ones in Canada and at High Tech Campus Eindhoven, Teledyne DALSA has grown out of the Canadian company DALSA founded in 1980. Since 2011 it is part of the larger US multinational Teledyne Technologies, headquartered in California. Where the Canadian office mostly produces professional cameras for applications like machine vision and space rovers, the Eindhoven business line specialises in X-ray detectors. The company’s image sensors are based on CMOS (Complementary Metal Oxide Silicon), a semiconductor technology used in computer and mobile phone chips that is more economical in power consumption and enables faster and better image performance.

“Because CMOS has a very high electron mobility and low electronic noise we’re able to make superior fluoroscopy videos with X-ray at a very low dose,” says Mila Heeman, marketing and business development manager for Teledyne DALSA Eindhoven. “Every X-ray detector can make static photos, but the dynamic video applications are really challenging, as many requirements have to be met at the same time, such as speed, resolution and clear images without ghosting. Most importantly, this has to be done at the lowest possible dose to protect both patient and staff.”

CMOS sensors are made from semiconductor wafers. However, where one wafer can provide thousands of computer chips for just as many applications, Teledyne DALSA’s X-ray detectors require the entire wafer, sometimes multiple wafers per detector depending on its size.

In the medical world Teledyne DALSA’s dynamic X-ray detectors are used in complex operations like replacing a heart valve or placing a stent or pacemaker, which involves the injection of a contrast medium into the blood vessels. “To see the contrast medium or the propagation of a catheter moving through the vessels a mere photograph is not enough,” says Heeman, “you need fast and clear images.” X-ray is also cheaper and works faster than a CT-scan, making it the most common imaging procedure in many surgical rooms. The obvious disadvantage of X-ray is its ionising radiation. Heeman: “Because CMOS makes our sensors extremely sensitive, the images have little noise so we can use very low doses of radiation.”

Canned food

Apart from the surgical room the company’s X-ray detectors are used in dental radiology for implants and orthodontics, as well as in mammography (breast cancer detection). As an industrial application it is used in so-called ‘non-destructive testing’ where products are checked with X-ray to see if they function properly. “Say you want to test whether the valve of a compressor functions well,” says Heeman. “You cannot see that from the outside, but X-ray enables you to look right through the material. With our dynamic method you can also see the movement of the valve as it is opening and closing.”

Other examples are corrosion monitoring of oil pipelines, quality control of soldering on printed circuit boards and quality control for canned food, where the X-ray allows you to see through the can without opening it.

Business is booming

Today Teledyne DALSA is the number one supplier in the surgery X-ray market and the number two detector supplier in dental X-ray applications. Their ambition is grow further and extend their products beyond the high-end systems to the larger volume mid-end systems. “The most important thing is that we continue to excel at producing high-grade medical devices and remain innovation leader in digital imaging,” says Heeman.

Being vertically integrated the company single-handedly takes care of the entire manufacturing process, from design to production. “It gives us the needed flexibility for our customers,” says Heeman. “Some of our US clients demand that production is done in North-America, which our Canadian production facility can provide. But for China and Europe it’s better to produce here.” Business is booming at the moment with production having doubled in the last five years. To support this growth the Eindhoven production facility has expanded its cleanroom and greatly increased its production capacity.

Colour X-rays

Teledyne DALSA continues to innovate and search for new technologies to implement, such as artificial intelligence and new sensor technologies. Currently they are looking at spectral imaging, which enables colour in X-ray images. Heeman: “Colour allows for much more detail in the X-rays, which can drastically improve diagnostics. In breast cancer screening for example doctors will be able to more easily detect micro-calcifications that could turn into cancer.”

Although the company has been part of the High Tech Campus from the very beginning, Heeman and her colleagues still enjoy the benefits. The company often works together on imaging research with Holst Centre, which is its direct neighbour on Campus. Teledyne DALSA also uses the facilities of its other neighbour, Philips Innovation Services, to conduct various measurements and research. “There are so many companies here to collaborate with,” Heeman says. “It’s a breeding ground for all kinds of technology, which inspires us to think creatively and motivates us to keep innovating.”